How do they work?

The safety light curtain consists of a transmitter and a receiver. The photoelectric generator projects a synchronized parallel infrared beam array to the receiving unit. But when the object interrupts the beam, the logic circuit in the light curtain will send a signal to the control system of the machine and stop the dangerous movement of the machine.

The transmitter contains light-emitting diodes (LEDs), which emit invisible infrared light pulses when powered by the light curtain timing and logic circuits. These light pulses are sequenced. One LED is energized one after another, and then it is modulated or pulsed at a predetermined frequency. The receiving unit is designed to only detect specific pulses and frequencies from the matched transmitter unit.

In order to meet the requirements for control and reliability, the safety light curtain continuously conducts self-inspection; if any failure is found in the self-inspection, the light curtain will like to send a stop signal to the machine control system. Then lock the light curtain in a safe state, know that the faulty component has been replaced and properly reset it.

The safety light curtain also has a set of two relays to provide a redundant circuit. If one relay fails, the second relay will still provide an endless signal.

When is it used?

Light curtain applications are usually classified according to the type of protection required. Light curtains are used to protect machines such as mechanical and hydraulic power presses, forming presses, stamping, forming and automatic assembly machinery. Safety devices are usually selected to protect the fingers or hands of the operator from being pinched by the machine.

If there is a boundary defined by a machine, robot or other equipment, you can choose a boundary protective light curtain.

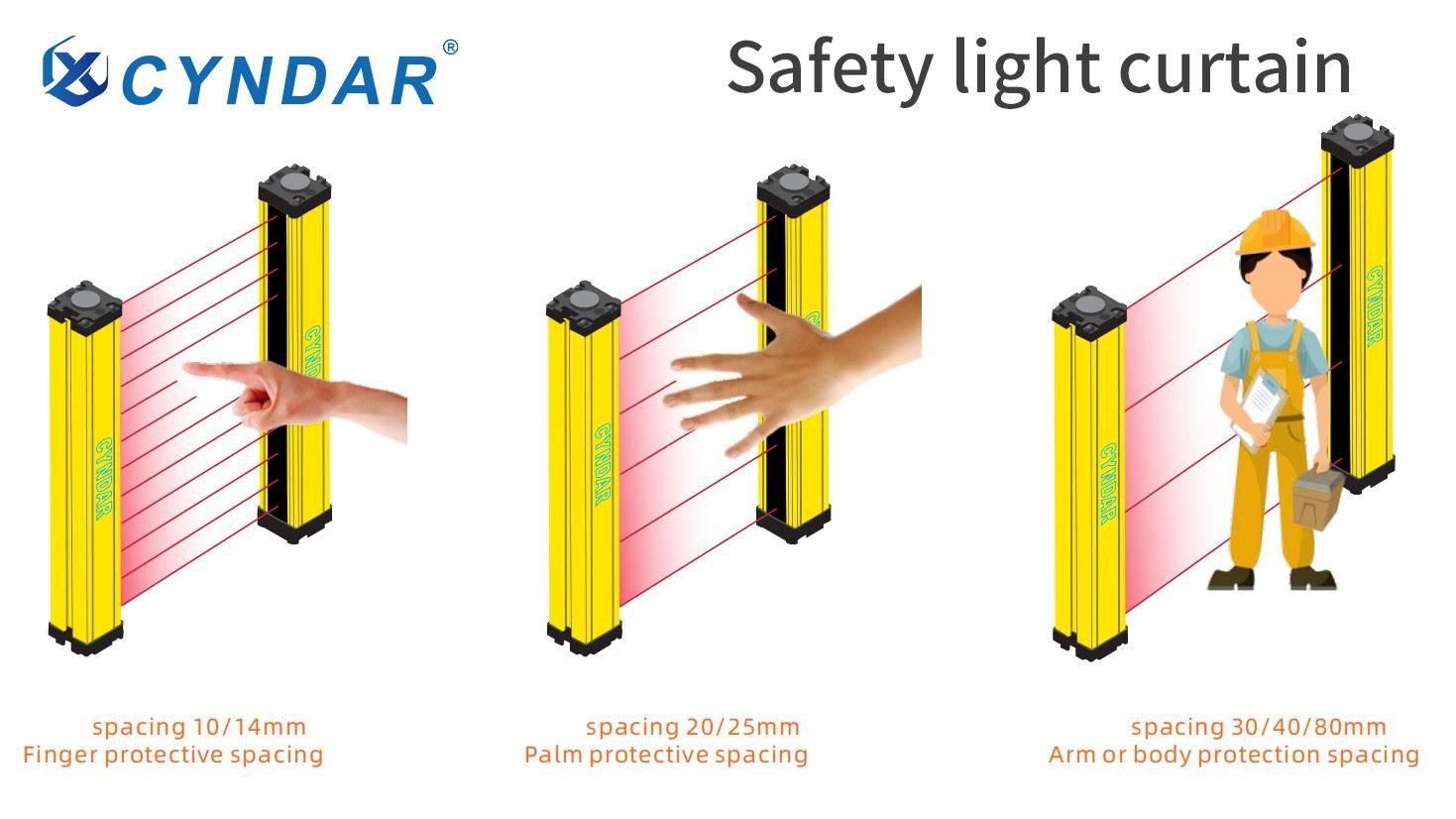

The main difference between a light curtain used to protect fingers and hands and a light curtain used to protect the periphery is the actual beam spacing. A unit for finger protection uses a 14mm gap between each beam, while a unit for hand protection has a 30mm gap between the beams. The beam spacing of the peripheral light curtain is 300mm to 500mm.

How to choose the right light curtain system?

Several points must be considered in order to make a precise choice; some of these factors include:

1. The size of the object or body part being detected or protected will determine the required beam spacing resolution; fingers 14 mm, hands 30 mm.

2. Determine the height and length of the area and the protection area to be protected. The maximum protection height required by the light curtain system will be determined.

3. The leave required for the machine or process to stop after the intermittent light curtain system will determine the response time required by the light curtain system.

4. The maximum separation or range required to separate the transmitter and receiver in the reference must be considered.

5. What type of load will the safety output of the light curtain control, and are they sufficient for the control circuit? This will determine the current capabilities required for the safety signal. Do you need semiconductor-type output or heavy-duty relay output to directly control the electric starter?

The applied risk assessment indicates what security level or security control category is required? Is the basic Class 2 rated light curtain device sufficient, or do you need a more robust Class 4 device to provide maximum protection and reliability for the application? All of these are points to consider when determining the right light curtain system.